Expertise

for the

Maritime Industry

Located in Hamburg, the private and independent Hamburg Ship Model Basin - HSVA - is a service and consulting company for clients in the maritime industry worldwide.

Our products contribute to a greener, more sustainable usage of marine environments. We help reduce emissions from shipping and we increase safety in marine transportation.

We are partners to our clients for the development of innovative, tailor-made solutions in shipping and offshore operations. For experimental investigations we are offering world class testing facilities.

Its leading role in national and international research programs makes HSVA a most competent partner in science and services in the field of maritime hydrodynamics, maritime aerodynamics and arctic technology as well as associated disciplines.

OUR FOCUS

Optimisation, Efficiency & Safety

We address any aspect in design, construction and operation of waterborne vehicles and structures that incorporate fluid mechanical considerations such as

- Resistance and Propulsion

- Ship Dynamics and Manoeuvring

- Seakeeping and Motions

- Cavitation and Hydroacoustics

- Structural Loads

- Underwater Vehicles

- Model experiments

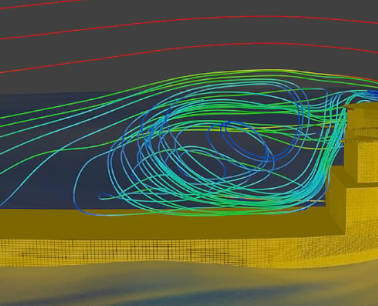

- Numerical computations (CFD)

- Field measurements

- Monitoring and data analytics

- In-house software

Design Loads, Operational Safety & Green Energy

HSVA adresses all aspects related to air flow on ships and offshore structures, including

- Wind Loads

- Air resistance

- Exhaust gas distribution

- Air Turbulence

- Ventilation

- Numerical Assessment (RANS, DES, LES)

- Wind Tunnel Testing

- IMO Weather Criterion

- Helicopter Operations

- Wind Propulsion Systems (Flettner Rotors, Soft Sails, Wing Sails)

- Wind Turbines

Safe operation in ice covered waters

Operating one of the very few testing facilities worldwide, HSVA provides unique expertise for marine vehicles and installations in ice covered waters:

- Icebreaking Vessels

- Design Assistance

- Arctic Environmental Conditions

- Ice Class Regulations and Requirements

- Model Testing in Ice

- Ice – Structure Interaction, Ice Loads

- Ice Performance Trials

- Wave – Ice Interaction

- Ice Mechanics

- Technical Assistance for Scientific Experiments in Ice

February 2024

HAPPY CHINESE NEW YEAR 2024 - 新年快乐 !

June 2023

HSVA at HafenCityRun2023

HSVA employees and their supporters took part in the HafenCityRun for a good cause. In excellent weather, the 4km run in Hamburg's impressive HafenCity was completed quickly. It was an enjoyable event, and we're already excited for next year's run.

July 2023

Newswave 2023 01

HSVA magazine "newswave" is now available online!

We are very glad to present the new edition of our magazine newswave in a brand new design!

Enjoy reading!

Jobs @ HSVA

HSVA is one of the world leading ship model basins. As a private company operating in the wonderful city of Hamburg, Germany, HSVA is active in the field of hydrodynamic research since 1913. Besides operating a large range of experimental facilities, we are among the forerunners of CFD developments and maritime applications.

read more